12 Best Ecommerce Inventory Management Software (2024)

Inventory management software for ecommerce stores is very important because it gives online sellers a comprehensive way to automate inventory tracking and order fulfillment for their business.

The best inventory management software for ecommerce offers retailers a clear way to monitor and track stock, automate purchase orders, and sync inventory levels across multiple channels and warehouses.

Best Ecommerce Inventory Management Software

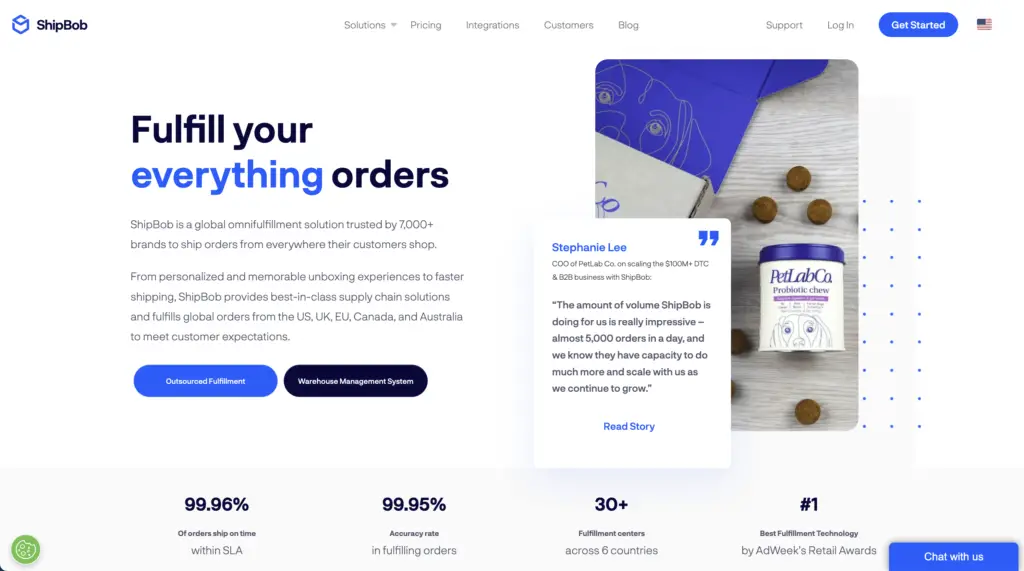

1. Shipbob

What We Liked

- The customer service team provides quick responses to user issues

- Next-day and 2-day shipping options for customer orders

- Expand business easily with multiple location options

- Easy-to-use interface that navigates easily from the dashboard

- The shipping rates are competitive and correlate to the size of your business

What Can Be Improved

- There can be a slight learning curve for beginners unfamiliar with logistics

- Some of their pages can have slow loading times

- The pricing structure of Shipbob can be a bit complex and confusing

Thousands of online stores use Shipbob for ecommerce inventory control. They have an all-in-one platform so users can manage production and end-to-end logistics of their customers’ orders.

The platform is simple and easy to use even if you don’t have a high level of IT or developer experience, so it can be a good fit even for smaller companies. Shipbob is best suited for stores with low SKU counts and high sales volume and has great pricing for sellers whose orders usually contain multiple items.

It easily integrates with major ecommerce platforms like Shopify, Amazon, Walmart, eBay, and others for quick logistics and deliveries to customers.

Pricing: Must contact the team for a quote

Free Tier: N/A

Best for: Best for businesses with few SKUs and large sales volume

2. Cin7

Cin7 is the best inventory management software for Shopify users. It is a robust system that has many different integrations with other business tools and has great stock tracking, automatic purchasing, and multi-warehouse functions.

It’s best for fast-growing online retailers who want a fulfillment system that is fully automated and easy to track ecommerce inventory. Their plans are all competitively and reasonably priced and connect with most online stores and marketplaces.

Cin7 offers top-to-bottom inventory and shipping management, including stock tracking and warehouse management features. Users can sync stock levels from multiple warehouses, track input parts for assembled goods, and automate purchase orders when they’re low on stock to avoid stockouts.

What We Liked

- 24/7 support from the customer service team is available

- Cin7 has great educational resources like tutorials and knowledge bases for users

- Track in-store sales alongside its online store inventory management tool

- Built-in Point-of-Sale program included with all plans

- Multi-warehouse automation is available with Cin7

What Can Be Improved

- Users must pay for an add-on that includes shipping services

- There are no EDI connections with the lowest-level plan

- There is no free trial unlike other ecommerce inventory management system options

Pricing: Starting at $399/month

Free Tier: No

Best for: Best for fast-growing stores with online and in-person storefronts

3. InFlow

InFlow is one of the best inventory management software for WooCommerce including features for stock tracking, purchasing and fulfillment, and other perks aimed at wholesalers.

In many cases, inFlow is best used for B2B businesses, supporting parts, assemblies, and finished unit tracking for multi-warehouse management. They have a virtual showroom using selected inventory for wholesalers to show clients data like pricing, minimum order quantities, and shipping times.

The platform can also be used for dropshipping businesses and to automate purchases of products when the store is running out of stock. This online store inventory software seamlessly integrates with many of the top ecommerce platforms and marketplaces, in addition to shipping proviers and third-party logistics companies.

What We Liked

- Customers can enjoy live phone support during business days

- Online resources like educational videos to help InFlow users

- The virtual showroom is a very useful tool for wholesalers to communicate with clients

- Customers can enjoy either monthly or annual billing for a discount

- Users can utilize a one-click quote, order, and invoice for B2B deals

What Can Be Improved

- Plans are based on monthly sales volume, so you may be pushed to a higher plan

- Users can only access the virtual showroom feature with the higher-tier plans

- It’s an electronic inventory management solution better suited for B2B companies than B2C

Pricing: Starting at $89/month

Free Tier: Yes, 14-day trial

Best for: Best for B2B businesses and dropshipping stores

4. Linnworks

Linnworks is the best ecommerce inventory management software for organizations with great technical and IT resources. The advanced functionality of the platform may not be a good match for all ecommerce stores, though for the right retailer, it can be very powerful.

The program connects and automates a wide range of ecommerce tasks and functions, which can support a multi-channel sales strategy for online stores. Linnworks can integrate with more than a hundred different business applications and tools, allowing for a centralized view and control over the store’s inventory, orders and fulfillment.

This inventory management software for ecommerce stores is a great resource to online sellers, especially those who need to manage multiple sales channels and warehouses.

What We Liked

- The platform continues to evolve and add new features for online sellers

- The customer support team is easily accessible and eager to help

- Provides users with real-time data and information to make timely decisions

- Allows users to reduce ordering errors and improve customer satisfaction

- Saves repetitive listing as users can list on multiple channels from Linnworks

What Can Be Improved

- There is a steep learning curve and isn’t beginner friendly

- The set-up process can be time-intensive and not very quick

- Pricing structure can be complex and isn’t transparent

Pricing: Must contact the team for a quote

Free Tier: N/A

Best for: Established businesses with advanced tech capabilities

5. Sortly

This is the best stock management system for ecommerce that is simple to use and an affordable platform for any online seller.

The system is not all-in-one for all shipping and logistics needs that an online seller may have, though it can be very good for its intended purposes.

The main draw to Sortly is the way it helps sellers easily track the quantities and locations of many different items, including online store inventory, office suppliers, input materials, and equipment.

Even though the platform can’t automatically make purchase orders when you’re running low, you can set reorder levels and low-stock notifications for specific items.

What We Liked

- Users can group items by storage location or other defining criteria

- The platform generates barcodes and QR codes for easy scanning and counting

- Free and low-cost plans are available

- You can easily check equipment, tools, supplies, and other goods in and out

- Great for smaller stores and nonprofit organizations

What Can Be Improved

- Not an all-in-one platform for logistics and shipping tasks

- You can only get scheduled phone support with the top plan from Sortly

- No purchase order function to replenish stock when you’re running low

Pricing: Starting at $0/month

Free Tier: Yes, 14-day trial

Best for: Good for small sellers

6. Skubana

Skubana is the best online store inventory management software for high-volume sellers. It has great integrations with top sales channels like Amazon, Walmart, and eBay, in addition to many other marketplaces.

This ecommerce inventory management platform is best for retailers who sell over multiple channels and want to automate their dropshipping tasks completely.

Skubana will track stock in multiple warehouses, outsourced fulfillment centers, FBA and WFS. The platform will sync in real time with all sales platforms to only show the inventory that the seller actually has to fulfill.

High-volume dropshippers can enjoy order routing automation, FTP and API connections to supplier data for high levels of customization to fit their needs.

What We Liked

- Extensive knowledge base available to Skubana users

- Automated workflows for dropshippers to become more efficient

- Users can sync inventory across multiple different sales channels

- Optimize inventory across Fulfillment by Amazon and Walmart Fulfillment Services

- Track stock across different warehouse locations anywhere in the world

What Can Be Improved

- This ecommerce inventory software isn’t a good fit for beginner users

- They don’t have transparent pricing that helps you compare with other platforms

- They don’t offer live support over the phone

Pricing: Ask the team to get a quote

Free Tier: N/A

Best for: Best for high-volume dropshippers

7. Katana

This is the best inventory management software for small manufacturers. It is a cloud-based solution, so it can easily be accessed from many devices and doesn’t need to be installed directly onto your computer.

Katana is a good fit for ecommerce businesses that need comprehensive inventory controls. Some of their top features for ecommerce stock management include production scheduling and planning, helping manufacturers stay on top of their orders to replenish their inventory as needed.

The platform helps users streamline their workflows across multiple ecommerce platforms, like WooCommerce and Shopify. Users can gain valuable insights into their manufacturing processes like production receipts, sales and purchase orders, warehouse status, and more.

What We Liked

- Simple and easy integrations with Shopify ecommerce platform

- Easily accessible from multiple devices since it’s a cloud-based platform

- Both phone and online support from customer service team

- Mobile-friendly to manage inventory online from your phone

- Great integrations with accounting tools and applications

What Can Be Improved

- Some processes in the platform aren’t as streamlined as they could be

- No calendar application within Katana’s system for time management

- Batch tracking system could be improved

Pricing: Starting at $99/month

Free Tier: Yes, 14-day trial

Best for: Best for small manufacturing companies

8. Acumatica

Acumatica is one of the best inventory management for ecommerce, especially since it’s a cloud-based platform that doesn’t need to be downloaded on your computer system. It’s not necessarily tailored for one industry or segment, so it can be a great automated resource for small and medium-sized retailers.

There are helpful reporting tools, dashboards, integrated document management, centralized security, and other customizations to make the platform fit your business’s needs.

The modular nature of Acumatica means it is easily customizable, and can be a wide platform like an enterprise-wide ERP or a more narrow solution depending on what you business requires.

The distribution management suite for Acumatica helps users manage purchasing, ordering, inventory tracking, and fulfillment.

What We Liked

- Modular platform means it is highly customizable to a business’s needs

- Cloud-based inventory management system for ecommerce is easily accessible

- Appealing pricing structure that does not charge per user

- Can replenish orders with an automated system

- Can manage items across warehouses, aisles, racks, shelves, and more

What Can Be Improved

- Can’t edit bills or receipts from the mobile app

- Customization abilities can get quite complex and require development knowledge

- The report design could use some improvements to be less clunky

Pricing: Must ask the team for a quote

Free Tier: N/A

Best for: Good for small and medium-sized businesses

9. Zoho Inventory

Zoho has a free inventory management solution that’s great for online stores with a more limited budget. The features and offerings aren’t as vast as other systems for inventory management for ecommerce, though it can work across multiple channels like eBay, Shopify, and Amazon.

From the platform, you can create purchase orders, manage the shipping of products, and track orders all from one central dashboard with helps with efficiency.

this is the best ecommerce inventory software for smaller stores, and as you grow, you can seamlessly integrate Zoho with other business management tools and applications. Zoho also offers advanced programs for accounting and administrative tasks as well.

What We Liked

- Zoho has a simple and easy-to-use interface that’s suited to beginners

- Seamless integration with other top business tools and applications

- Easy to track orders and provide customer service

- Combines ecommerce inventory control with a CRM resource

- Works seamlessly with other Zoho products like Zoho Books for accounting

What Can Be Improved

- Some of the features are a bit too simplistic for certain business’s needs

- Can’t customize the templates very much

- Backorder feature can create troubles for the rest of the customer’s order

Pricing: Starting at $0/month

Free Tier: Yes, includes 1 warehouse and 50 orders/month

Best for: small-scale businesses

10. Ordoro

This is the best inventory management software for dropshipping, which is free for all users. There is a paid premium version you can access with more advanced features, though the free plan tends to provide all that small and medium-sized online stores need from a logistics platform.

Ordoro helps users become more efficient with automated shipping and logistics processes, as it can be used to track assets, secure the best shipping rates, integrate sales channels, assign barcodes for fewer shipping errors, and create purchase orders when you need to restock.

The automatic inventory tracking system from Ordoro allows business owners to take a hands-off approach to the logistics side of their business when they run a dropshipping store.

What We Liked

- Heavily-discounted shipping rates from the United States Postal Service

- Choice to ship from an array of shipping carriers like FedEx, DHL, UPS, USPS, etc.

- Users can print shipping labels in batches or individually

- You can set up your own automation rules and shipping presets

- Quickly launch a dropshipping business with Ordoro

What Can Be Improved

- Synching orders from different sales channels can take a few minutes

- Can’t integrate with Zapier and a few other common business applications

- Purchase order abilities and other features only available at higher-tier plans

Pricing: Starting at $0/month

Free Tier: Yes, for 1,000 orders a month and 1 shipping channel

Best for: Dropshipping ecommerce stores

11. Netstock

Netstock is a great website inventory management tool for online stores to optimize their business process across different sales channels. The product is highly adaptable and allows users to change and respond in real time with their supply chain decisions.

They are known for their great customer service and data visualization capabilities. Netstock provides users with a helpful dashboard highlighting inventory KPIs, forecasts, seasonality, generated purchase orders, and more.

Netstock helps online sellers optimize their business tasks by providing them with large-scale forecasting accuracy, coordination across the enerprise, and great data on inventory turnover and capacity utilization.

What We Liked

- The dashboard is simple and easy to use, even for beginners

- There is a great cusotmer service team that is eager to help with customer issues

- Easy to see a visual overview of a store’s stock and where there can be changes

- The system will highlight priorities for the business owner to take care of

- Good tool for long-term inventory planning

What Can Be Improved

- The forecasting functionality can be limited based on the user’s needs

- Cannot edit one-time spikes in demand from forecasting systems

- May lack some of the advanced features of other inventory management software for small ecommerce business

Pricing: Must contact the team to get a quote

Free Tier: N/A

Best for: Best for medium-sized businesses optimizing their supply chain

12. Lightspeed

Lightspeed is one of the top inventory management systems for online sellers, helping users add new products and monitor stock levels with ease. Sellers can manage all their different channels from one centralized location, which can be very useful as the business expands.

They offer a cloud and browser-based system, even offering an iOS app for mobile use. Lightspeed is liked by users for its top-tier inventory management solutions and 24/7 customer support.

The advanced offerings of Lightspeed make it a better choice for established businesses rather than newer stores. However, Lightspeed’s ecommerce product management software has great features like unique serial numbers, product variants, and built-in purchase orders for better efficiency for online sellers.

What We Liked

- All users get a dedicated account manager upon paying for a plan

- Lightspeed provides 24/7 support for its customers questions and concerns

- The inventory management system is comprehensive and superior to others

- Seamless integrations with many other business tools and applications

- A good fit for established businesses

What Can Be Improved

- Customers get locked in to long contracts that are not easy to cancel

- You can only get discounted prices if you lock into longer contracts

- There are more affordable options available from others on this list

Pricing: Starting at $69/month

Free Tier: Yes, 14-day trial

Best for: Well-established businesses

How to Pick the Right Inventory Management Software for Ecommerce?

Inventory management in ecommerce means online sellers are tracking stock levels properly to replenish as needed and have enough on hand to fulfill customers orders.

This can be difficult when done by hand across multiple warehouses and sales channels, so a good ecommerce software with inventory management that automates these tasks is key to many sellers.

Number of Users and Locations

Your inventory management software should be able to support the number of users and different locations that make up your business.

Many software plans will only support a certain number of users and locations before you will have to move up to the next-tier plan and pay more.

Analytics and Reporting

Go for an inventory management system that provides you with the analytics and reporting you need to make supply chain decisions for your business.

Make sure reporting and analytics dashboards are easily accessible and straightforward so you can get clear insights into your inventory and logistics.

Multi-Channel Support

You may consider a multi-channel ecommerce inventory management system when you sell across multiple marketplaces and channels.

Sellers will need a sophisticated system that can sync across these channels and keep one set of inventory data so you can know when to reorder and avoid a stockout of popular items.

Look for systems that integrate easily with the main platforms like Amazon, eBay, Shopify, and others.

Integrations

Make sure you find an inventory tracking system that will seamlessly integrate with the other business tools and resources you use. This may include shipping providers, accounting software, and others.

This will make sure that you have all important business information in one place to make informed inventory decisions rather than having to navigate between multiple systems to get the information you need.

Support Quality

Only some inventory tracking platforms will have 24/7 support or phone support. Otherwise, the platforms will offer live chat support or via email.

Both of these features are very important to make sure that you have the support you need, when you need it so all inventory management tasks can run smoothly.

Ease of Use

An inventory management software should be user-friendly and easy to use given the resources of your business.

If you don’t have an IT team or developer knowledge yourself, go for one of the simpler programs that is easier to set up and suited for beginners.